அறிமுகம்:

This line is special design for automatic feeding the bulkgraunle product bagging in to 25kg and 50 kg plastic .According the client requirement we also need offer the automatic conveying and palletizing line .The seller completed the design, manufacturing and supply of the production line in strict accordance with the technical requirements and combined with its own packaging line design experience in the sugar industry.

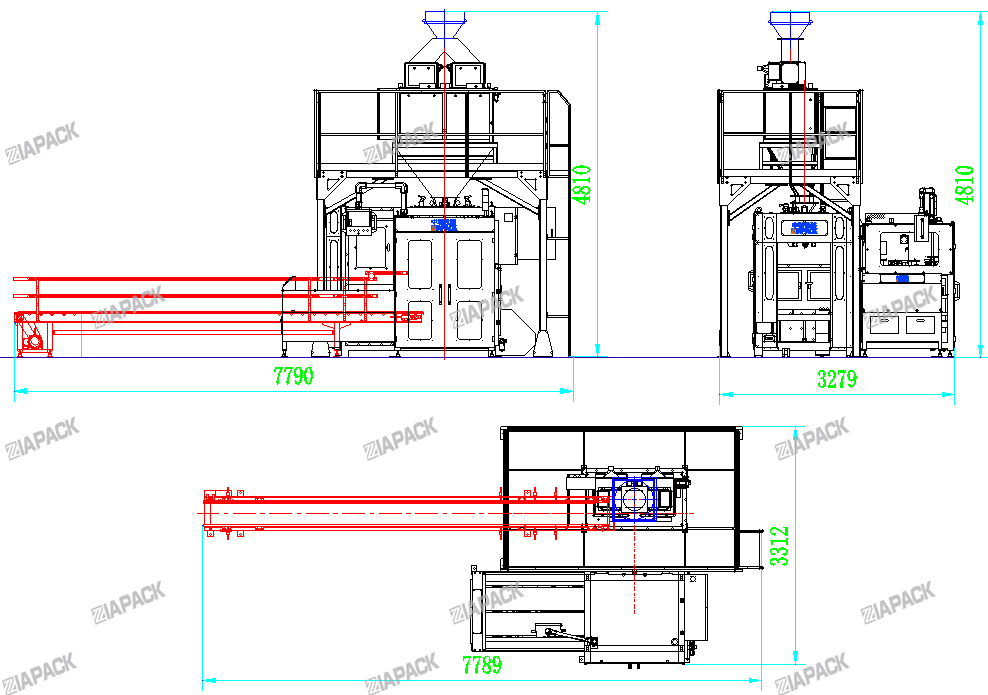

ZL25K-S Automatic double buckets gravity scale system

பிrinciple :

This scales are composed of mechanical components and sensors of the weighing system and a weighing control instrument system. Main machine frame and material contact parts made by sus304.Including vibrating feeding for accuracy feeding and Fast feeding by valve discharge .Install with Mettler Toledo weighing sensor .The whole process of feeding, weighing and unloading loose bags is automatically controlled and self-locking.

அம்சங்கள்:

1,Equipped with a standard cabinet,Main electric are China famous brand

2,All equipment is equipped with local operation columns, and the packaging machine is equipped with on-site local control display panels.

3,The weighing box adopts a frame structure, which is stable as a whole and has good sealing performance. The sensors are fixed on the frame of the weighing box. Three weighing pressure sensors per scale are fixed on the frame of the weighing box. It has an independent cover, which is dustproof and anti-collision.Equipped with two dust removal interfaces and breathing holes.

4,The fast discharge door of the weighing hopper adopts a 45º tapered half-open material bottom door.The discharging speed is very fast, and the vibration generated by the cylinder will not affect the weighing accuracy.

5,All mechanical transmissions use dust-proof bearing transmission, and there is no sliding friction between metals.

6,All doors on the scale body are well sealed and there is no dust leakage.

7,All bolts and nuts inside the weighing box are protected by steel wires and cotter pins. (Use a lock nut or drill a hole at the end of the screw, and then thread it with stainless steel wire)

8,The overall external wires and air pipes are all made of closed stainless steel tubes, which are neat and beautiful. There is a dust removal interface on the scale body

9,Parts in direct contact with the material are all made of stainless steel304 and polished

Parameter setting

| மாதிரி | Net weight sensor type electronic scale (double scale) |

| Feeding method | Gravity blanking |

| பொருள் | Material contact surface304 stainless steel, frame protection painted steel |

| காற்று நுகர்வு | ~200NL/min |

| power | ~2.0kw |

| Weighing capacity | ≥600 bags/hour |

| Set weighing value | Net weight 25-50kg/bag |

| துல்லியம் அளவிடும் | ±0.1% |

| load cell | மெட்லர் டோலிடோ |

ZLZD750 AUTOMATIC BAGGING MACHINE

இந்த அலகு ஒரு பை சேமிப்பு தொட்டி, பை எடுத்து வரிசைப்படுத்தும் சாதனம், பை ஏற்றும் ரோபோ, பை இறுக்கி இறக்கும் சாதனம், பை தள்ளும் சாதனம், பை வாய் வழிகாட்டி சாதனம், வெற்றிட அமைப்பு மற்றும் கட்டுப்பாட்டு அமைப்பு ஆகியவற்றைக் கொண்டுள்ளது.

அம்சங்கள்

1).பேக்கேஜிங் பைகளுக்கு பரந்த தகவமைப்பு.பேக்கேஜிங் இயந்திரம் பை எடுக்கும் முறையைப் பின்பற்றுகிறது, அதாவது, பை தயாரிப்பு கிடங்கிலிருந்து பை எடுக்கப்படுகிறது, பை மையப்படுத்தப்பட்டு நிலைநிறுத்தப்படுகிறது, பை முன்னோக்கி அனுப்பப்படுகிறது, பை வாய் நிலைநிறுத்தப்படுகிறது, பை முன்கூட்டியே திறக்கப்படுகிறது, பை ஏற்றுதல் கையாளுபவர் பை வாயைத் திறக்க கத்தியை பை வாயில் செருகுகிறார், பின்னர் பையை மேலே இழுக்கிறார்.

2). பை ஏற்றுதல் கையாளும் கை ஒரு சர்வோ மோட்டாரால் இயக்கப்படுகிறது. பெரும்பாலான பிற உற்பத்தியாளர்களின் நியூமேடிக் கையாளும் கருவிகளுடன் ஒப்பிடும்போது, இது வேகமான வேகம், மென்மையான பை ஏற்றுதல், தாக்கம் இல்லாதது மற்றும் நீண்ட சேவை வாழ்க்கை போன்ற நன்மைகளைக் கொண்டுள்ளது.

3). பை கிளாம்பிங் மற்றும் இறக்குதல் சாதனம், பை கிளாம்பிங் திறப்பில் இரண்டு அருகாமை சுவிட்சுகளுடன் பொருத்தப்பட்டுள்ளது, இவை பேக்கேஜிங் பை திறப்பு முழுமையாக இறுக்கப்பட்டுள்ளதா மற்றும் பை திறப்பு முழுமையாக திறக்கப்பட்டுள்ளதா என்பதைக் கண்டறியப் பயன்படுகின்றன. இது பேக்கேஜிங் இயந்திரம் தவறாக மதிப்பிடுவதில்லை மற்றும் தரையில் பொருட்களைக் கொட்டுவதில்லை என்பதை உறுதி செய்கிறது, இது பேக்கேஜிங் இயந்திரத்தின் பயன்பாட்டுத் திறனையும், தளத்தில் செயல்படும் சூழலையும் மேம்படுத்துகிறது.

4). பேக்கேஜிங் இயந்திரத்தின் அளவுரு அமைப்பு தொடுதிரையில் நிறைவடைகிறது. மனித-இயந்திர நட்பு தொடுதிரை செயல்பாட்டு இடைமுகம் முழு இயந்திரத்தின் இயக்க நிலையை விரிவாகக் கண்காணிக்க முடியும். தானியங்கி தவறு காட்சி மற்றும் செயலாக்க முறை அறிவுறுத்தல்கள் பராமரிப்பு பணியாளர்கள் மிகக் குறுகிய காலத்தில் பிழையைச் சமாளிக்க அனுமதிக்கின்றன.

5) சோலனாய்டு வால்வுகள் போன்ற நியூமேடிக் கூறுகள் மற்றும் தொடுதிரைகள் மற்றும் எடையிடும் கருவிகள் போன்ற துல்லியமான தயாரிப்புகள் அனைத்தும் சீல் வைக்கப்பட்டு வெளிப்பாடு இல்லாமல் நிறுவப்பட்டுள்ளன. அவை தூசி நிறைந்த சூழல்களில் பயன்படுத்த ஏற்றவை, இது உபகரணங்கள் நீண்ட ஆயுளைக் கொண்டிருப்பதை உறுதி செய்கிறது.

6) பேக்கேஜிங் இயந்திரத்தின் அனைத்து கட்டுப்பாட்டு கூறுகளும் நிர்வாக கூறுகளும் பிரபலமான உள்நாட்டு மற்றும் வெளிநாட்டு நிறுவனங்களால் தயாரிக்கப்படுகின்றன, இது உபகரணங்களின் நீண்டகால, நிலையான மற்றும் நம்பகமான செயல்பாட்டை உறுதி செய்கிறது.

7) இது ஒரு தவறு சுய-கண்டறிதல் செயல்பாடு மற்றும் எழும் எந்தவொரு பிரச்சனையையும் உடனடியாக எச்சரிக்க ஒரு கேட்கக்கூடிய மற்றும் காட்சி எச்சரிக்கை அமைப்பைக் கொண்டுள்ளது.

8) எளிமையான மற்றும் வசதியான இயக்க தளம், ஆபரேட்டர்கள் இயந்திரத்தை இயக்குவதையும் கண்காணிப்பதையும் எளிதாக்குகிறது.

தொழில்நுட்ப அளவுருக்கள்:

பேக்கேஜிங் திறன் 600 பைகள் / மணி

கட்டுப்பாட்டு முறை நிரல்படுத்தக்கூடிய கட்டுப்படுத்தி (PLC)

பொருள்: பொருள் தொடர்பு மேற்பரப்புக்கு 304 துருப்பிடிக்காத எஃகு, சட்ட பாதுகாப்புக்கு 304 துருப்பிடிக்காத எஃகு, முதலியன.

Set weighing value Net weight 30kg/package

காற்று நுகர்வு ~ 600NL/நிமிடம்

மின்சாரம் AC 380V 50Hz ~ 15kw